news, people, new vacuum pumps, mergers and acquisition

to the latest news

Pfeiffer Vacuum acquires vacuum component manufacturer Asslar, Dec. 2009 Pfeiffer Vacuum Technology AG announces the signing of a contract to acquire Trinos Vakuum-Systeme GmbH of Göttingen, Germany. By expanding the Pfeiffer Vacuum portfolio to include the high-quality vacuum components, chambers and systems from Trinos Vakuum-Systeme, the company can now offer its customers throughout the world even more comprehensive solutions for their vacuum needs. more |

Oerlikon Leybold Vacuum is selling its Oerlikon Leybold Vacuum Scandinavia business unit

Oerlikon Leybold Vacuum is selling its Oerlikon Leybold Vacuum Scandinavia business unit

Göteborg/Köln, Nov. 16, 2009 Oerlikon Leybold Vacuum is selling its Oerlikon Leybold Vacuum Scandinavia business unit in Göteborg to the unit's management. The corresponding contracts are effective as of October 31st, 2009. Dr Andreas Widl, CEO of Oerlikon Leybold Vacuum, said: “We are consequently following up on our strategy to streamline the portfolio of Leybold Vacuum. more |

Ajeet Singh appointed director of Edwards Oct. 29, 2009 Hong Kong, 29 October 2009 - Leading vacuum and abatement equipment manufacturer Edwards, announces the appointment of Ajeet Singh to the board of Edwards Group Limited as a director. more |

Gardner Denver Nash Service Center expands in Nuremberg Nuremberg, Oct. 27, 2009 Gardner Denver Nash has restructured its European service activities. Beginning in October, 2009, in-house repairs in Germany have been centralized at the Service Center in Nuremberg. more |

Pfeiffer Vacuum concludes capital project Asslar, Oct. 21, 2009 Pfeiffer Vacuum announces the conclusion of extensive capital investments in manufacturing and logistics. - Total volume reaches Euro 20 million - State-of-the-art vacuum pump manufacturing and logistics - Company gearing up for post-crisis recovery The installation of new systems, equipment and processes has been ongoing for the past two years. The project included the renovation, modernization and realignment of turbopump and backing pump manufacturing operations, as well as construction of a Logistics Center. mehr |

NASH liquid ring compressors for offshore operation Nuremberg, 07.10.2009 Offshore oil platforms make unique demands of the systems installed. The Norwegian StatoilHydro relies on NASH NAB 1500 two stage liquid-ring compressors for operation on the Gjøa Platform in the North Sea. more |

new technology and innovation for your trusty NASH CL pumps Trumbull, CT, Aug. 4, 2009 Making a classic even better... With Nash’s ECO-FLO CL upgrade line, your water usage can be reduced by 50% The NASH CL is the most popular liquid ring vacuum pump ever built. Now, the engineers at Nash have brought new technology and innovation to your trusty NASH CL pumps. more |

to the videos: Man climbs building with vacuum gloves

to the videos: Man climbs building with vacuum gloves

A man has climbed up a BBC building using a pair of vacuum gloves he built himself, in a stunt for a new BBC One science show. Inventor Jem Stansfield, the presenter of Bang Goes The Theory, used an everyday vacuum cleaner to construct the kit. He scaled the 40m (120ft) high BBC White City building in west London, watched by hundreds of people. This stunt was carried out by trained professionals following strict safety procedures and should not be attempted or replicated. more |

Graham Corporation Receives $3.4 million Ejector System Order July 31, 2009 Graham Corporation, a manufacturer of critical equipment for the oil refinery, petrochemical and power industries, today announced that it has been awarded a $3.4 million ejector system order for an oil refinery in China. more |

Pfeiffer Vacuum with sound development in the 1st half year of 2009 Asslar, Germany, July 28, 2009 - Sales advance even during economic crisis - Profitability remains high - Order backlog up year on year While Pfeiffer Vacuum was unable to completely elude the impact of the financial and economic crisis during the 1st half year of 2009, the company’s position continued to develop well. more |

Agilent Technologies to Acquire Varian, Inc. for $1.5 Billion SANTA CLARA, Calif. & PALO ALTO, Calif. - Jul. 27, 2009 Agilent Technologies Inc. (NYSE:A) and Varian, Inc. (NasdaqGS:VARI) today announced that they have signed a definitive agreement for the acquisition by Agilent of Varian, a leading worldwide supplier of scientific instrumentation and associated consumables for life science and applied market applications. The acquisition broadens Agilent’s applications and solutions offerings in Life Sciences, Environmental, and Energy and Materials. It also expands Agilent’s product portfolio into atomic and molecular spectroscopy; establishes a leading position in NMR, imaging and vacuum technologies; and strengthens its consumables portfolio. “This acquisition is a major step in Agilent’s transformation into a leading bio-analytical measurement company,” said Bill Sullivan, Agilent’s president and chief executive officer. more |

Introducing the NASH Vectra XL 750 Liquid Ring Vacuum Pump & Compressor Trumbull, CT, July 27, 2009 Gardner Denver Nash is pleased to introduce its newest member of the Vectra series of liquid ring pumps and compressors: the NASH Vectra XL 750. more |

The world’s fastest paper machines operate with NASH liquid ring vacuum pumps Nuremberg, 24.07.2009 At regular intervals, RISI runs tests and reports on the world’s fastest paper machine. However, what the results do not indicate is that 84% of these installations rely on NASH liquid ring vacuum pumps for dewatering and the vacuum system. more |

Gardner Denver, Inc. Reports Second Quarter 2009 Financial Results Strong Cash Flow Used to Repay Debt and Profit Improvement Initiatives Remain on Schedule more |

The new OmniStar™ and ThermoStar™ gas analysis systems Asslar, Germany, June 9, 2009 With OmniStar™ and ThermoStar™, Pfeiffer Vacuum offers two benchtop analysis systems for precise monitoring of process analysis for up to 128 different gases. OmniStar and ThermoStar are also suitable for reliably identifying unknown gases. Even low detection limits can be swiftly and easily determined for condensable gases. more |

Varian, Inc. Introduces First True Benchtop Ion Trap GC/MS Palo Alto, CA, June 3, 2009 Varian, Inc. today announced the release of the 225-MS, a true benchtop GC/MS (gas chromatograph/mass spectrometer). The 225-MS ion trap is the world's first mass spectrometer to enclose all of its components, including the foreline vacuum pump, in one compact design. more |

Michael C. Arnold Joins Gardner Denver, Inc. Board of Directors QUINCY, IL, Jun 03, 2009 Gardner Denver, Inc. (NYSE: GDI) announced today that its Board of Directors appointed Mr. Michael C. Arnold to serve as an independent director of the Company until the 2012 annual meeting of its stockholders and until his successor is duly appointed and qualified. Mr. Arnold will serve on the Board's Management Development and Compensation Committee. more |

Introducing the NASH Vectra SX Series of Liquid Ring Vacuum Pumps & Compressors Trumbull, CT, May 11, 2009 Gardner Denver Nash is pleased to introduce its newest line of industrial liquid ring pumps and compressors: the NASH Vectra SX series. Designed from the ground up to meet the widespread needs of the process industry, the Vectra SX adds five models to Nash's Vectra series in the 1.5 to 10 HP range, providing the right solution for small capacity vacuum pump requirements. Designed to use less energy and consume less operating liquid than competitive models, it is possible to save the user as much as 40% on power consumption and 50% on water usage. more |

Gardner Denver, Inc. announces manufacturing consolidation project QUINCY, IL (April 13, 2009) Gardner Denver, Inc. (NYSE: GDI) announced the consolidation of the North American manufacturing operations of its compressor and vacuum pumps used in OEM applications into its Monroe, Louisiana facility. Production from the Company’s Sheboygan, Wisconsin operations will be transferred to Louisiana over the next twelve months. The project is expected to be completed by March 31, 2010. more |

Pfeiffer Vacuum - Best results in the company’s history. Dividend again raised. Asslar, Germany, March 25, 2009. Pfeiffer Vacuum, one of the leading manufacturers of high-quality vacuum pumps, measurement equipment and complete vacuum systems, announces its full, audited results for the 2008 fiscal year, which surpassed expectations. With a proposed dividend of € 3.35 per share and a dividend yield of 7.1 percent, Pfeiffer Vacuum is the highestdividend issue in the TecDAX. more |

Oerlikon Leybold Vacuum introduces compact vacuum pump for analytical applications Cologne, Germany, March 17, 2009 Oerlikon Leybold Vacuum introduces compact single-stage rotary pump for analytical applications, including mass spectrometry more |

Only the Manufacturer's vacuum pump service can guarantee expert maintenance and repairs Nuremberg (Germany), Mar. 12, 2009 No two service contracts are the same and a low quotation for the repair of a pump should not be the only decisive argument for placing an order. Again and again, the operators of pumps and systems find this a somewhat painful experience. A case in point can be seen in the repair of two liquid ring vacuum pumps in a paper mill. more |

HiPace™ Plus Turbopump - Ideal for analytical applications! Asslar, Deutschland, March 11, 2009 In addition to the current new product line of HiPace 10-700 l/s turbopumps, Pfeiffer Vacuum has brought to market new compact yet powerful turbopumps under the name, HiPace 300 Plus. more |

Erich Mohrdieck and Roger McMahon Co-Presidents of SIHI March 9, 2009 Christoph v. Grolman, Co-CEO of TBG Holdings NV (TBG) and Chairman of SIHI Group BV Supervisory Board (SIHI), is pleased to announce the promotion of Erich Mohrdieck and Roger McMahon to Co-Presidents of SIHI more |

Edwards to supply liquid ring pumps for new power station in India Crawley, UK, Feb. 18, 2009 Leading vacuum technology company Edwards has won a multi-million Euro contract to supply liquid ring vacuum pump systems for three 660MW generating units at the Super Thermal Power Project Stage 1 at Sipat, State of Chattisgarh, India. The contract has been awarded by OJSC Power Machines of Russia, who are supplying the majority of the equipment for the power station. It will be run by NTPC, India’s largest power generating company. more |

Siemens Receives SSAB Contract for Vacuum Tank Degassing Facility Atlanta, Georgia, USA, Jan 28, 2009 Svenskt Stål AB (SSAB) has awarded Siemens a contract for more than $14 million for a Vacuum Tank Degassing (VTD) facility for its Mobile, Ala. facility. Siemens is scheduled to complete the VTD project in May 2010. This VTD project is part of a major investment program announced by SSAB in August 2008 with the aim to further develop the company’s production base in Sweden and the United States. The investment will result in a major increase of the volume of quenched and tempered steels. The installation of the VTD facility will enable SSAB to provide more value-added products to its customers. more |

Spire Corporation and Hind High Vacuum Company enter into Photovoltaic Strategic Relationship BEDFORD, Mass., Jan. 2009 Spire Corporation (Nasdaq: SPIR), a global solar company providing turnkey factories and capital equipment for manufacturing photovoltaic (PV) modules and cells worldwide, today announced it has finalized a strategic relationship with Hind High Vacuum Company Private Limited (HHV) located in Bangalore, India. Spire and HHV shall cooperate to better address the Indian PV industry by offering a more complete and competitive portfolio of solar manufacturing equipment and service capabilities. more |

The Future of Freeze Drying: Lyophilization Jan. 2009 A quicker and less labor intensive freeze drying process and the possibility of producing loose and free-flowing powder at low temperatures and low pressures, all in one vessel: According Hosokawa the newly developed Active Freeze Drying technology is a big step in the world of freeze drying and powder technology. more |

Pfeiffer Vacuum acquires vacuum component manufacturer

Asslar, 2. Dez. 2009

- Even more extensive solutions offerings through Trinos Vakuum-Systeme GmbH

- Synergy effects through complementary products

- Acquisition to be financed in cash

Pfeiffer Vacuum Technology AG announces the signing of a contract to acquire Trinos Vakuum-Systeme GmbH of Göttingen, Germany. Under the terms of the agreement, Pfeiffer Vacuum will acquire 100 percent of the shares in Trinos effective January 1, 2010. The purchase price will be financed in cash. Confidentiality has been agreed regarding the total volume of the transaction.

By expanding the Pfeiffer Vacuum portfolio to include the high-quality vacuum components, chambers and systems from Trinos Vakuum-Systeme, the company can now offer its customers throughout the world even more comprehensive solutions for their vacuum needs. The expertise possessed by the two companies in developing and engineering new technologies is also complementary. All regions and market segments will benefit from this acquisition, in particular the North America region and the analytical, coating and research & development segments.

Pfeiffer Vacuum Chief Executive Officer Manfred Bender explains: "Of all of the potential acquisitions that we have recently reviewed, Trinos Vakuum-Systeme makes for the best fit with us. The company is young, fast growing, profitable and active in the same markets we are. Trinos has a very good name in the marketplace. With this move, Pfeiffer Vacuum is taking a further step along the road to becoming a full-line provider of vacuum applications. We are convinced that Trinos' integration into our worldwide sales and service network will be swift, and we intend to work together to generate further growth."

Trinos Vakuum-Systeme GmbH was formed in 1997 by Peter Spreitz and Marcus Weinhagen. The company employs a workforce of around 140 people. Sales revenues in fiscal 2008 totaled some € 18 million. In September 2009, Trinos was awarded the SME Grand Prix from the Oskar Patzelt Foundation. Pfeiffer Vacuum plans to retain and expand the location in Göttingen, along with all of its employees. The two former owners will remain with the company as managing directors.

|

| Manfred Bender (CEO Pfeiffer Vacuum),

Peter Spreitz und Marcus Weinhagen (both managing directors Trinos Vakuum-Systeme), Dr. Matthias Wiemer (member of the board Pfeiffer Vacuum) |

Questions and answers related to Pfeiffer Vacuum acquisition of Trinos Vakuum-Systeme

Press contact:

Pfeiffer Vacuum GmbH - www.pfeiffer-vacuum.com

Sabine Neubrand, Public Relations, email: Sabine.Neubrand@pfeiffer-vacuum.de, Tel. +49 (0)6441 802-169, Fax +49 (0)6441 802-883

Oerlikon Leybold Vacuum is selling its Oerlikon Leybold Vacuum Scandinavia business unit

Göteborg / Köln, Nov. 16, 2009

Oerlikon Leybold Vacuum is selling its Oerlikon Leybold Vacuum Scandinavia business unit in Göteborg to the unit's management. The corresponding contracts are effective as of October 31st, 2009. Dr Andreas Widl, CEO of Oerlikon Leybold Vacuum, said: “We are consequently following up on our strategy to streamline the portfolio of Leybold Vacuum. In view of the size and structure of the Scandinavian markets, this step fits best the present focus which entails concentration on faster growing emerging markets in other regions. I am convinced that with the MBO we have found the best solution for all stakeholders involved and that the new management will run the vacuum business successfully.”

The Managing Director of Oerlikon Leybold Vacuum Scandinavia, Christer Bengtsson, explains that the name of the new company ‘Low2High Vacuum’ says it all: “We will continue to serve our customers with everything from low to high vacuum, with the expertise and application know-how we have acquired over almost five decades in the Scandinavian vacuum technology markets. We benefit from a very good market position, and are going to expand and leverage the traditional business in both existing and new attractive markets. We see ourselves as a company firmly anchored in the region.”

Leybold Vacuum first entered the Scandinavian market in 1962 as Nordiska Heraeus AB, changing names in 1967 to Leybold Heraeus AB. Starting as a sales representative, Christer Bengtsson joined the company in 1976. After Heraeus sold Leybold to Degussa, the name changed to Leybold AB in 1988. Being appointed to Managing Director in 2005, Christer Bengtsson also accompanied the enterprise during the last name change in 2006, when Leybold AB became Oerlikon Leybold Vacuum Scandinavia AB. With this management-buy out, the company immediately obtained the status of Distributor to Oerlikon Leybold Vacuum and will thus ensure smooth delivery of the renowned vacuum products.

Offering sales and service on vacuum technology to the Scandinavian countries Sweden and Norway, the new company Low2High Vacuum will profit from the experience within the structures of a larger company. The staff of 11 extremely well trained employees is committed to working with the existing and prospective customers to serve and build on their global success as the company is setting off into a new future.

For further information please contact:

Oerlikon Leybold Vacuum GmbH - www.oerlikon.com - Bonner Strasse 498, 50968 Köln, Germany

Christina Steigler, christina.steigler@oerlikon.com, Tel. +49 (0) 221 347-1261

Ajeet Singh appointed director of Edwards

Hong Kong, 29 October 2009

Leading vacuum and abatement equipment manufacturer Edwards, announces the appointment of Ajeet Singh to the board of Edwards Group Limited as a director. Ajeet Singh is a Partner of Unitas Capital based in Hong Kong. Prior to joining Unitas, he was President, Asia Pacific for Emerson Network Power. In the past, he has held this position for Emerson Climate Technologies and was President Asia-Pacific across all of Emerson's businesses.

“I look forward to drawing on Ajeet’s 27 years of experience of being in a global engineering and technology environment similar to ours. The fact that much of his time in business has been in Asia will help guide our growth and strategy formulation in the region," said Nigel Hunton, Chief Executive Officer, Edwards.

Stephen Welton, Chairman of Edwards, added, “On behalf of the board I am delighted to welcome Ajeet as a director. I am confident that his long experience of operating in Asia at the highest levels of a respected industrial player will bring significant benefits to Edwards."

www.edwardsvacuum.com

Gardner Denver Nash Service Center expands in Nuremberg

Nuremberg, Oct. 27, 2009

Gardner Denver Nash has restructured its European service activities. Beginning in October, 2009, in-house repairs in Germany have been centralized at the Service Center in Nuremberg.

With the integration of the two former German service sites, Wetzlar and Nuremberg, a larger service center for the entire Nash pump range has been established in Nuremberg. While the Wetzlar service center has been closed, a new aftermarket sales office was opened nearby.

At the Nuremberg site, a six-figure investment was made in machines, installations and workstations. As a result, capacity in the coating and sand-blasting areas has been significantly increased. The repair times have therefore been reduced and the flexibility of Nash on-site service has increased. Furthermore, due to the integration, synergies have grown in the fields of warehousing, new pump assembly and mechanical manufacturing.

The service activities also benefit from the existing on-site manufacturing capacities: Modern machining centers and cranes for heavy loads can also be used by the service technicians. The location of Nuremberg, at the heart of Europe and at the intersection of important freeways, was an additional reason for this decision.

Christof Przybille, Aftermarket Europe Manager, states: “Nash can provide much better service with the bundling of the activities at the Service Center in Nuremberg. Thanks to the reduced processing times, the downtimes and idle times in our customers’ manufacturing processes are reduced still further.”

download: Gardner Denver Nash Service Center expands in Nuremberg (pdf-Version)

About the Company:

Gardner Denver Nash is the Nash Division of Gardner Denver, Inc. Originating from nash_elmo Industries, the company is the world's leading manufacturer of liquid ring vacuum pumps, compressors and engineered systems. For more than 100 years, Gardner Denver Nash has engineered and produced liquid ring pumps and vacuum and compressor systems for the most demanding applications in a variety of fields and industries.

Nash - Zweigniederlassung der Gardner Denver Deutschland GmbH - www.GDnash.com

Wolfgang Kraft, Marketing, wolfgang.kraft@gardnerdenver.com, Tel. +49 (0)911 1454-7771, Fax +49 (0)911 1454-7777

Pfeiffer Vacuum concludes capital project

Asslar, Oct. 21 2009

Pfeiffer Vacuum announces the conclusion of extensive capital investments in manufacturing and logistics.

The installation of new systems, equipment and processes has been ongoing for the past two years. The project included the renovation, modernization and realignment of turbopump and backing pump manufacturing operations, as well as construction of a Logistics Center. At the same time, the company has been optimizing all process steps on a cross-departmental basis.

- Total volume reaches Euro 20 million

- State-of-the-art vacuum pump manufacturing and logistics

- Company gearing up for post-crisis recovery

|

| Pfeiffer Vacuum new logistic center |

|

| Pfeiffer Vacuum new manufacturing center |

"We have been utilizing the current economic situation in invest, to expand our capacities and to optimize all of our processes. With these moves, we are gearing up for the next recovery phase," is how Pfeiffer Vacuum Chief Executive Officer Manfred Bender explains the company's activities.

Now located on 30,000 m² of covered area are two cutting-edge production lines, which advance the products to the new Logistics Center situated in the middle. The greatest challenge in renovating and reengineering the manufacturing operation was to conduct these activities without any interruption to regular production operations. The entire production flow was reversed, with outdated machinery and equipment being replaced. A new logistics concept for materials is being employed in the turbopump manufacturing operation. It includes the installation of a bar stock warehouse, an automated transport system and a so-called "supermarket" - a provisioning warehouse for the components needed in the manufacturing process.

"Our goal is to achieve greater flexibility in our production operations. The focus, in addition to a clear alignment toward the needs of our customers, is to optimize in-production inventories. Thanks to faster throughput times, the latter also ultimately benefits our customers," notes Dr. Matthias Wiemer, the member of the Pfeiffer Vacuum Management Board whose responsibilities also include production.

The newly constructed Logistics Center, which was inaugurated in August 2008, houses an automated small-component warehouse with 6,000 bin spaces and a high-bay warehouse with 1,200 pallet spaces. This is where the aim of delivering every order in the form of a single package is coming to fruition. The employment of special warehouse management software coordinates the picking of products from the two warehouses and assures a smooth shipping operation.

"What's important is an integrated wall-to-wall solution that incorporates all production steps, right through to delivery," is the way Manfred Bender sums up the project. "We manufacture high-tech products and work very closely with our customers. And this also has to be reflected in our manufacturing operations."

Contact:

Pfeiffer Vacuum Technology AG - www.pfeiffer-vacuum.com

Sabine Neubrand, Public Relations, email: Sabine.Neubrand@pfeiffer-vacuum.de, Tel. +49 (0)6441 802-169, Fax +49 (0)6441 802-883

NASH liquid ring compressors for offshore operation

|

Nuremberg, 24.07.2009

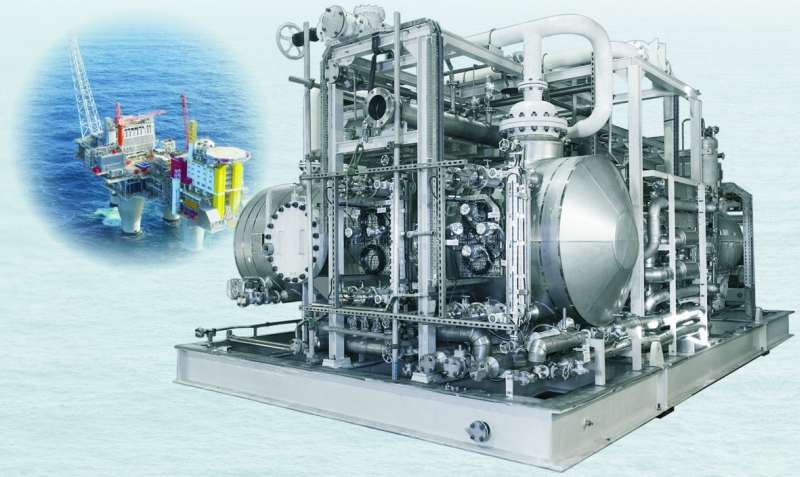

Offshore oil platforms make unique demands of the systems installed. The Norwegian StatoilHydro relies on NASH NAB 1500 two stage liquid-ring compressors for operation on the Gjøa Platform in the North Sea.

With the development of the Gjøa Platform in the North Sea, northwest of Bergen, Norway, new crude oil and gas reserves are being developed. Gjøa uses a NASH NAB 1500 two stage liquid ring compressor system to extract and compress hydrocarbons and nitrogen from the crude oil. The system was designed for a volume flow rate of 1500 m³/h and a compression pressure of 6 to 9 bar absolute. Owing to the special composition of scavenged gases, it was necessary to use Duplex stainless steel for the compressor. In order to win the contract for this system, the supplier of the casted parts had to provide, among other things, certification complying with NORSOK.

Both Nash compressors are mounted on a single, large 8 x 5 m base frame together with motors, separator, heat-exchanger, etc. Consequently, the entire system creates low vibrations and is very quiet. The engineering and assembly of the installation was done by the Norwegian company, K.Lund Offshore AS.

The working conditions at sea, under the toughest climatic conditions and often far from special maintenance and service facilities, demand a high level of operational reliability. NASH compressors fulfill these requirements, having been characterized for years by their reliability – one of the many reasons why StatoilHydro selected NASH liquid-ring compressors. Two stage compressors of the NASH NAB model range have a suction capacity of up to 3800 m³/h and reach a compression pressure of up to 15 bar absolute.

StatoilHydro is the international market leader in the use of “Deepwater Technology” and the world’s largest operator in water depths exceeding 100 m. The Gjøa field is newly developed and should go into production in 2010. Currently, it is the largest project in the North Sea.

download: NASH liquid ring compressors for offshore operation (pdf-Version)

About the Company:

Gardner Denver Nash is the Nash Division of Gardner Denver, Inc. Originating from nash_elmo Industries, the company is the world's leading manufacturer of liquid ring vacuum pumps, compressors and engineered systems. For more than 100 years, Gardner Denver Nash has engineered and produced liquid ring pumps and vacuum and compressor systems for the most demanding applications in a variety of fields and industries.

Nash - Zweigniederlassung der Gardner Denver Deutschland GmbH - www.GDnash.com

Wolfgang Kraft, Marketing, wolfgang.kraft@gardnerdenver.com, Tel. +49 (0)911 1454-7771, Fax +49 (0)911 1454-7777

new technology and innovation for your trusty NASH CL pumps

Trumbull, CT - Aug. 4, 2009

Making a classic even better...

With Nash’s ECO-FLO CL upgrade line,

your water usage can be reduced by 50%

The NASH CL is perhaps the most popular liquid ring vacuum pump ever built.

The reason? Nash rock solid reliability.

Now, the engineers at Nash have brought new technology and innovation to your trusty NASH CL pumps.

Nash has used its unrivaled knowledge of liquid ring pumping to improve the legendary CL design with new ECO-FLO patent-pending technology.

The results:

- Same reliability, same performance

- Lower operating costs

- A “green” vacuum pump

ECO-FLO Benefits:

- Reduces water usage by up to 50%

- Inlet and discharge piping are unchanged - no process piping changes

- Uses existing base, motor and drive

- Potential payback of less than 12 months

- Overhaul to exacting Nash standards at a Nash Service Center

- Available in both cast iron and stainless steel

- Nash warranty

Let Nash show you how you can make your plant “greener.”

download: NASH CL - ECOFLOW upgrade (pdf-Version)

Gardner Denver Nash - www.GDnash.com - 9 Trefoil Dr., Trumbull, CT 06611 USA

Amy Harold, Marketing Specialist, nash@gardnerdenver.com, Tel. 1-800-553-NASH

Man climbs building with vacuum gloves

July 2009

|

|

A man has climbed up a BBC building using a pair of vacuum gloves he built himself, in a stunt for a new BBC One science show.

Inventor Jem Stansfield, the presenter of Bang Goes The Theory, used an everyday vacuum cleaner to construct the kit.

He scaled the 40m (120ft) high BBC White City building in west London, watched by hundreds of people.

This stunt was carried out by trained professionals following strict safety procedures and should not be attempted or replicated.

more about vacuum handling

Graham Corporation Receives $3.4 million Ejector System Order

July 31, 2009

Graham Corporation, a manufacturer of critical equipment for the oil refinery, petrochemical and power industries, today announced that it has been awarded a $3.4 million ejector system order for an oil refinery in China.

The ejector system will be installed at an oil refinery in Hunan Province, China, and is expected to be shipped in the first quarter of fiscal 2011, which ends June 30, 2010. Equipment for this order will be built both in Graham’s Batavia, New York facility and by a local fabricator in China. Local manufacture in China of certain components is required by the end user. Graham received this order earlier this month, at the start of the Company’s fiscal 2010 second quarter, and it is therefore not included in the order activity reported for the Company’s first quarter that was separately announced today.

James R. Lines, Graham’s President and Chief Executive Officer, commented, “This order will represent Graham’s seventh ejector system installation in China over the past three years and is testament both to the global strength of our brand and to the inroads we have made in the Chinese market through our Suzhou-based subsidiary. We see tremendous future opportunity to expand our business in China as that country continues to invest in new oil refining and petrochemical production capacity.”

www.graham-mfg.com

Pfeiffer Vacuum with sound development in the 1st half year of 2009

Asslar, Germany, July 28, 2009

- Sales advance even during economic crisis

- Profitability remains high

- Order backlog up year on year

While Pfeiffer Vacuum was unable to completely elude the impact of the financial and economic crisis during the 1st half year of 2009, the company’s position continued to develop well.

download: Key figures at a glance

In these times of global recession, Pfeiffer Vacuum has succeeded in increasing its revenues for the 1st half of 2009 by 2.9 percent over the same period the year before. A major contract from the solar industry for vacuum systems used for thin layer coating of solar cells played a major role in the sales revenue rise. This contract, which the company had received last year, is recognized in sales on percentage-of-completion-basis. All work is progressing on schedule.

Regionally, Germany continues to account for the largest share of total sales revenues at 44.3 percent. Pfeiffer Vacuum was able to boost sales on its home market by 27.9 percent to € 43.6 million. Totaling € 25.3 million, sales in the other countries of Europe were down 15.8 percent from the year before. In the United States, Pfeiffer Vacuum’s sales revenues advanced by 8.4 percent year on year to € 17.8 million. However, this rise was essentially attributable to exchange rate effects; expressed in U.S. dollars, sales revenues declined by 6.2 percent. At € 11.9 million, sales revenues in Asia and the rest of the world were down 22.2 percent year on year.

In terms of the sales mix by markets, the Coating segment remained far and away in first place, with sales revenues here surging by 57.0 percent to € 34.2 million in the first half of 2009. Sales revenues in the Analytical market segment declined by 12.1 percent to € 21.4 million. The heterogeneous market segment of Industrial Applications saw sales slip by 22.7 percent to € 17.4 million. On the other hand, increased public-sector investments in connection with the implementation of various international economic stimulus programs sparked sales revenue growth of 12.0 percent to € 16.5 million in the Research & Development sector. At € 4.2 million, sales revenues in the Chemical and Process Technology segment remained on the prior year’s level, while the overall weakness of the semiconductor industry drove sales revenues down by 40.5 percent to € 4.9 million.

In comparison with the extremely strong period the year before the company saw new orders decline by 22.6 percent to € 80.0 million during the 1st half of 2009. What is noteworthy in this connection, though, is that the € 41.6 million in new orders during the 2nd quarter of 2009 represented an 8.3 percent rise over the 1st quarter of 2009. At € 42.4 million, the level of order backlog at the end of June 2009 was up 2.7 percent over the previous year. The assumption that the downturn has bottomed out in the 1st quarter seems to prove true.

Pfeiffer Vacuum continues to focus on cost control and on sustaining high margins. Yet the product mix, economies of scale and costs in conjunction with the modernization and reorganization of the turbopump production facilities burdened gross margin, which at 43.6 percent was down 3.4 percentage points from the year before. This effect, coupled with intensified selling activities, caused the EBIT margin to decline by 3.2 percentage points to 22.2 percent. However, these margins rank Pfeiffer Vacuum a leader in the industrial environment.

Following payment of the dividend in the total amount of € 28.5 million on May 27, 2009, cash and cash equivalents as at June 30, 2009, totaled € 47.4 million, shareholders’ equity € 125.6 million. At 85.3 percent, the equity ratio of debt-free Pfeiffer Vacuum at the close of the second quarter of 2009 continued to remain far above average levels.

Chief Executive Officer Manfred Bender comments: 'The effects of the economic crisis is now strongly noticeable in the mechanical engineering industry. Nevertheless, we were able to record sound development of our business in the first half of 2009. Our policy of a broad-based alignment of our vacuum solution business and our ability to offer leading technology in any number of fields is paying off. Particularly our engagement in research and development is enabling us to expand our know-how in forward-looking growth sectors. Highly promising opportunities are opening up for example in the field of modern energy supply. We are presently conducting intensive talks with the purchasing and development departments at many customers relating to future projects. However, we do not have the visibility to predict when these talks will manifest themselves in the form of concrete orders. Yet we can nevertheless reiterate our guidance calling for sales revenues potentially declining by up to 10 to 15 percent in a worst-case scenario, as well as an EBIT margin in excess of 20 percent for the full 2009 fiscal year.'

download: Attachment: Balance Sheet, Income and Cash Flow Statements

Pfeiffer Vacuum Technology AG - www.pfeiffer-vacuum.com

Dr. Brigitte Looß, Investor Relations, email: Brigitte.Looss@pfeiffer-vacuum.de

Tel. +49 (0)6441 802-346, Fax +49 (0)6441 802-365

Agilent Technologies to Acquire Varian, Inc. for $1.5 Billion

SANTA CLARA, Calif. & PALO ALTO, Calif. - Jul. 27, 2009

Agilent Technologies Inc. (NYSE:A) and Varian, Inc. (NasdaqGS:VARI) today announced that they have signed a definitive agreement for the acquisition by Agilent of Varian, a leading worldwide supplier of scientific instrumentation and associated consumables for life science and applied market applications. Agilent will pay $52 cash per share of common stock for Varian in a transaction that represents a premium of approximately 35% to Varian’s closing price on July 24, 2009. Both Agilent’s and Varian’s Board of Directors have unanimously approved the all-cash offer.

The acquisition broadens Agilent’s applications and solutions offerings in Life Sciences, Environmental, and Energy and Materials. It also expands Agilent’s product portfolio into atomic and molecular spectroscopy; establishes a leading position in NMR, imaging and vacuum technologies; and strengthens its consumables portfolio.

“This acquisition is a major step in Agilent’s transformation into a leading bio-analytical measurement company,” said Bill Sullivan, Agilent’s president and chief executive officer. “While we continue to be a world leader in electronic measurement, our biggest opportunities for future growth are in bio-analytical measurement.”

“For more than 60 years, Varian has built rich talent, technology, products and relationships in this area. The combination of Varian with Agilent’s bio-analytical measurement business will result in the broadest product offering in the industry. The acquisition will establish Agilent as a clear market leader in analytical solutions and give us the talent and technology base for creating unique new products and markets,” added Sullivan.

“After thorough review together with our independent advisors, our Board of Directors determined that this transaction delivers excellent value for our shareholders,” said Garry Rogerson, chairman and chief executive officer of Varian, Inc. “We also anticipate that the combination will yield strong benefits for our customers and employees. Like Agilent, Varian has a long history as a technology leader. We each bring expertise and experience across a different but complementary set of markets and applications. For instance, while Agilent is a leader in food safety, Varian is well established in the energy industry, and has a broad spectrum of products for environmental analysis. Together, the combined company will be able to provide customers with the most comprehensive set of solutions across a wider range of industries.”

Once the acquisition has been completed, Adrian Dillon, Agilent’s executive vice president and chief financial officer, will assume responsibility for combining Varian with Agilent’s Bio-Analytical Measurement segment consistent with Agilent’s operating model. “We have the opportunity to create significant value for Agilent shareholders by leveraging the combined entity’s infrastructure and global supply chain,” said Dillon.

The transaction is expected to generate $75 million in annual cost synergies and achieve Agilent’s 20% return on invested capital (ROIC) target within four to five years. The transaction is subject to approval by the shareholders of Varian and will be completed after achieving customary closing conditions and regulatory approvals, which Agilent expects before calendar year-end. The transaction is not subject to any financing conditions.

Agilent in Bio-Analytical Measurement

Agilent’s bio-analytical measurement business provides application-focused solutions that include instruments, software, consumables and services that enable customers to identify, quantify and analyze the physical and biological properties of substances and products. Agilent is a global leader in gas chromatography and gas chromatography/mass spectrometry, and liquid chromatography and liquid chromatography/mass spectrometry used to analyze the composition of air, water, food, drugs, industrial process streams and forensic evidence.

About Varian, Inc.

Varian, Inc. is a leading worldwide supplier of scientific instruments and vacuum technologies for life science, environmental, energy, and applied research and other applications. The company provides complete solutions, including instruments, vacuum products, laboratory consumable supplies, software, training and support through its global distribution and support systems. Varian, Inc. employs approximately 3,600 people worldwide and operates manufacturing facilities in North America, Europe and Asia Pacific. Varian, Inc. had fiscal year 2008 sales of $1.0 billion, and its common stock is traded on the NASDAQ Global Select Market under the symbol “VARI.” Further information is available on the company’s Web site at www.varianinc.com.

About Agilent Technologies

Agilent Technologies Inc. (NYSE:A) is the world’s premier measurement company and a technology leader in communications, electronics, life sciences and chemical analysis. The company’s 19,000 employees serve customers in more than 110 countries. Agilent had net revenues of $5.8 billion in fiscal 2008. Information about Agilent is available on the Web at www.agilent.com.

Additional Information and Where to Find It: Varian, Inc.

Varian, Inc. (“Varian”) plans to file with the Securities and Exchange Commission (the “SEC”) and furnish to its stockholders a proxy statement in connection with the proposed merger with Cobalt Acquisition Corp., pursuant to which Varian would be acquired by Agilent Technologies, Inc. (the “Merger”). The proxy statement will contain important information about the proposed Merger and related matters. INVESTORS AND STOCKHOLDERS ARE URGED TO READ THE PROXY STATEMENT CAREFULLY WHEN IT BECOMES AVAILABLE. Investors and stockholders will be able to obtain free copies of the proxy statement and other documents filed with the SEC by Varian through the Web site maintained by the SEC at www.sec.gov. In addition, investors and stockholders will be able to obtain free copies of the proxy statement from Varian by contacting Investor Relations by telephone at +1 (650) 424-5471, by mail at Varian, Inc., 3120 Hansen Way, Palo Alto, Calif., 94304-1030, Attn: Investor Relations, by e-mail at ir@varianinc.com, or by going to Varian’s Investor Relations page on its corporate Web site at www.varianinc.com (click on “Investors,” then on “SEC Filings”).

Varian and its directors and executive officers may be deemed to be participants in the solicitation of proxies from the stockholders of Varian in connection with the proposed Merger. Information regarding the interests of these directors and executive officers in the transaction described herein will be included in the proxy statement described above. Additional information regarding these directors and executive officers is also included in Varian’s proxy statement for its 2009 Annual Meeting of Stockholders, which was filed with the SEC on December 19, 2008. This document is available free of charge at the SEC’s Web site at www.sec.gov, and from Varian by contacting Investor Relations by telephone at +1 (650) 424-5471, by mail at Varian, Inc., 3120 Hansen Way, Palo Alto, Calif., 94304-1030, Attn: Investor Relations, by e-mail at ir@varianinc.com, or by going to Varian’s Investor Relations page on its corporate Web site at www.varianinc.com (click on “Investors,” then on “SEC Filings”).

Varian’s Forward-Looking Statements

This press release contains certain forward-looking statements within the meaning of Section 27A of the Securities Act of 1933 and Section 21E of the Securities Exchange Act of 1934. These forward-looking statements involve certain risks and uncertainties that could cause actual results to differ materially from those indicated in such forward-looking statements, including, but not limited to, the ability of the parties to consummate the proposed Merger, satisfaction of closing conditions precedent to the consummation of the proposed Merger, the ability of Agilent to successfully integrate Varian’s operations and employees, the ability to yield benefits for customers and employees, and such other risks as identified in Varian’s Annual Report on Form 10-K for the fiscal year ended Oct. 3, 2008, and Varian’s most recent Quarterly Report on Form 10-Q, each as filed with the SEC, which contain and identify important factors that could cause the actual results to differ materially from those contained in the forward-looking statements. Varian assumes no obligation to update any forward-looking statement contained in this press release.

Agilent’s Forward-Looking Statements

This news release contains forward-looking statements as defined in the Securities Exchange Act of 1934 and is subject to the safe harbors created therein. These forward-looking statements are based on Agilent’s current expectations relating to the proposed acquisition of Varian by Agilent, including the expected closing of the transaction and the benefits thereof. These statements are not guarantees of future performance and are subject to certain risks, uncertainties and assumptions that are difficult to predict. Therefore, actual results could differ materially and adversely from those expressed in any forward-looking statements as a result of various factors. Important factors that may cause such a difference for Agilent include, but are not limited to, the possible failure to satisfy necessary conditions to the closing of the merger including the risk that necessary regulatory approvals for the merger are not obtained, the risk that the transaction is not consummated within the expected timeframe, difficulties in integrating the two businesses, the failure to achieve anticipated cost synergies and the effects of the transaction making it more difficult to maintain existing relationships with employees, customers or business partners. The forward-looking statements contained herein include, but are not limited to, information regarding expected annual cost savings and the ROIC resulting from the transaction, the expectation that the deal will be accretive to Agilent earnings on a non-GAAP basis in the first full year after closing, the enhancement of our product portfolio and our ability to address a wider range of customer needs, the anticipated growth of our business in the bio-analytical measurement market, the ability of the combined company to provide improved products, services and support to its customers, and achieving anticipated benefits and synergies from the combined entity’s infrastructure, global supply chain, and worldwide sales and support organization. These forward-looking statements involve risks and uncertainties that could cause Agilent’s and Varian’s results to differ materially from management’s current expectations. Such risks and uncertainties include, but are not limited to, the risk that the transaction does not close or that closing is delayed, the risk that the integration of Varian is more expensive or time-consuming than we expect, the risk that we are unable to realize expected synergies or that the realization is delayed, risks associated with changes in demand for Agilent’s and Varian’s products, and risks associated with the development generally of our overall strategic objectives.

In addition, other risks that Agilent faces in running its operations include the ability to execute successfully through business cycles; ongoing competitive, pricing and gross margin pressures; the impact of geopolitical uncertainties on our markets and our ability to conduct business; the ability to improve asset performance to adapt to changes in demand; the ability to successfully introduce new products at the right time, price and mix and other risks detailed in Agilent’s filings with the Securities and Exchange Commission, including its Quarterly Report on Form 10-Q for the period ended April 30, 2009. Forward-looking statements are based on the beliefs and assumptions of Agilent’s management and on currently available information. Agilent undertakes no responsibility to publicly update or revise any forward-looking statement.

Source: Agilent Technologies Inc.

Further technology, corporate citizenship and executive news is available on the Agilent news site at www.agilent.com

Introducing the NASH Vectra XL 750 Liquid Ring Vacuum Pump & Compressor

Trumbull, CT - July 2009

Gardner Denver Nash is pleased to introduce its newest member of the Vectra series of liquid ring pumps and compressors: the NASH Vectra XL 750.

Designed from the ground up to meet the widespread needs of the process industry, the Vectra XL 750 extends Nash’s Vectra series to the largest capacity ever.

The NASH Vectra XL 750 series features reliable long life, high efficiency, and the flexibility to tailor the pump to your specific needs:

o Reliability - Low operating speeds ensure a long, reliable operating life.

o Vacuum and Compressor Capability

- Vacuum pump operation to 28.5” HgV

- Compressor operation to 30 PSIG

- O-Ring Sealing

- Oil Lubrication

o ATEX Certification Pending

o Single Point Inlet & Discharge Connections

- Eliminates the the need for manifolds, simplifying process piping, saving space and reducing the installed cost

o Materials of Construction and Availability

- Ductile iron – available now

- All 316L stainless steel - available in February, 2010

Reliability, efficiency and flexibility, coupled with the comprehensive Gardner Denver Nash expertise, service and technical support, provide you with unmatched value in liquid ring pumps.

Gardner Denver Nash - www.GDnash.com - 9 Trefoil Dr., Trumbull, CT 06611 USA

Amy Harold, Marketing Specialist, nash@gardnerdenver.com, Tel. 1-800-553-NASH

The world’s fastest paper machines operate with NASH liquid ring vacuum pumps

Nuremberg, 24.07.2009

At regular intervals, RISI runs tests and reports on the world’s fastest paper machine. However, what the results do not indicate is that 84% of these installations rely on NASH liquid ring vacuum pumps for dewatering and the vacuum system.

In January 2008, the latest RISI report concerning “The World’s fastest Paper and Board Machines” was published. A total of 25 paper machines, in different categories worldwide, were identified as the fastest installations in their class.

For Gardner Denver Nash, manufacturer of vacuum and dewatering systems for paper machines, this report has an additional and entirely different meaning. According to company records, NASH liquid ring vacuum pumps are fitted to 84% of these paper machines. For the company, this is more outstanding proof that the market primarily targets proven and, more importantly, reliable technology.

The great flexibility of a vacuum system based on NASH liquid ring vacuum pumps guarantees sufficient capacity even if maintenance work is carried out on individual machines. Continuous operation of the dewatering system - and the complete paper machine - is guaranteed as a result. Another important reason for using NASH liquid ring pumps is that they are not vulnerable to liquid carry-over and fibers in the air stream. Consequently, even minor faults in the process cycle do not influence the drainage system’s function.

|

download: The world’s fastest paper machines operate with NASH liquid ring vacuum pumps (pdf-Version)

About the Company:

Gardner Denver Nash is the Nash Division of Gardner Denver, Inc. Originating from nash_elmo Industries, the company is the world's leading manufacturer of liquid ring vacuum pumps, compressors and engineered systems. For more than 100 years, Gardner Denver Nash has engineered and produced liquid ring pumps and vacuum and compressor systems for the most demanding applications in a variety of fields and industries.

Nash - Zweigniederlassung der Gardner Denver Deutschland GmbH - www.GDnash.com

Wolfgang Kraft, Marketing, wolfgang.kraft@gardnerdenver.com, Tel. +49 (0)911 1454-7771, Fax +49 (0)911 1454-7777

Gardner Denver, Inc. Reports Second Quarter 2009 Financial Results

QUINCY, IL, Jul 23, 2009 - Gardner Denver, Inc. (NYSE: GDI)

Strong Cash Flow Used to Repay Debt and Profit Improvement Initiatives Remain on Schedule

Second Quarter Highlights:

Diluted Earnings Per Share ("DEPS") were $0.48 for the second quarter of 2009, which included expenses for profit improvement initiatives, non- recurring items, impairment charges and the related income tax effect that reduced DEPS by $0.02. Excluding these items, DEPS would have been $0.50.

Cash provided by operating activities exceeded $37 million for the quarter, including $33 million as a result of inventory reductions.

Debt was reduced by $26.5 million, primarily due to repayments of $37 million which were partially offset by the unfavorable effect of changes in foreign currency exchange rates.

Profit improvement projects are being implemented on schedule.

download the report: Jul 23, 2009 - Gardner Denver, Inc. Reports Second Quarter 2009 Financial Results

download the report: Jul 23, 2009 - CORRECTION - Gardner Denver, Inc. Reports Second Quarter 2009 corrected table

www.GardnerDenver.com

The new OmniStar™ and ThermoStar™ gas analysis systems

Asslar, 9. Juni 2009

Qualitative and quantitative gas analysis

Mass spectrometry is an analytical method that is used for identifying chemical elements and compounds. With OmniStar™ and ThermoStar™, Pfeiffer Vacuum offers two benchtop analysis systems for precise monitoring of process analysis for up to 128 different gases.

OmniStar™ and ThermoStar™ are also suitable for reliably identifying unknown gases. Even low detection limits can be swiftly and easily determined for condensable gases.

Modular design and diverse applications

The analysis systems consist of a heated and temperature-regulated gas inlet system, the PrismaPlus mass spectrometer, a dry diaphragm vacuum pump and the HiPace turbopump. They are suitable for both qualitative and quantitative gas analysis. In this connection, the units cover the mass ranges of 1 to 100 amu, 1 to 200 amu and 1 to 300 amu. Their capillary inlet enables a virtually segregation-free gas supply. A pressure-regulated gas inlet is optionally available for changing pressures. The units feature a capillary of either stainless steel (OmniStar) or quartz (ThermoStar), which can be heated up to 350 °C by means of a heating hose. This prevents vapors from condensing during the process analysis.

The ThermoStar™ gas analysis unit is a version that is specially designed for being coupled with thermo scales. High-temperature gas samples can be admitted by means of a quartz capillary.

Both of these units offer convincingly simple handling. They can be directly connected and are ready for immediate use. Thanks to their compact dimensions, OmniStar and ThermoStar can be set up virtually anywhere and are additionally highly mobile. The user interface is user friendly, and all unit-specific parameters can be read on the backlit LCD display. Fields of application range from chemical processes to the semiconductor industry, metallurgy, fermentation, catalysis and laser technology right through to environmental analysis.

Contact:

Pfeiffer Vacuum GmbH - www.pfeiffer-vacuum.com

Sabine Trylat, Public Relations, email: Sabine.Trylat@pfeiffer-vacuum.de, Tel. +49 (0)6441 802-169, Fax +49 (0)6441 802-883

Varian, Inc. Introduces First True Benchtop Ion Trap GC/MS

Palo Alto, CA, June 3, 2009

Varian, Inc. today announced the release of the 225-MS, a true benchtop GC/MS (gas chromatograph/mass spectrometer).

The 225-MS ion trap is the world’s first mass spectrometer to enclose all of its components, including the foreline vacuum pump, in one compact design.

Intended for use in high-throughput laboratories for applications ranging from environmental analyses to product safety, the 225-MS addresses the issue of space limitations while offering improved performance at the same time.

Mass spectrometers require two pumps to achieve sufficient vacuum: a foreline pump which is typically situated on the laboratory floor and a turbomolecular pump located inside the instrument. Without increasing the size of the mass spectrometer, the 225-MS integrates both pumps inside the benchtop unit, eliminating the floor space and hose required by an external pump.

The innovative integrated pump design offers important performance and ownership benefits:

- It reduces the background signal which allows improved sensitivity.

- The vacuum module does not require oil changes, eliminating the inconvenience of changing (and disposing of) the oil.

The 225-MS offers MS/MS and MSn capability to reduce matrix influences and provide more detailed structural information. Users can also take advantage of liquid or gas reagent based chemical ionization (CI) for compound confirmation and increased selectivity. The result is enhanced qualitative and quantitative information about the sample.

"Combining Varian's expertise in vacuum technologies and mass spectrometry, the 225- MS delivers a compact solution without compromising performance," said Martin O’Donoghue, Senior Vice President, Scientific Instruments, Varian, Inc. "In fact, the innovative design increases the sensitivity of the instrument."

For More Information, Contact:

Varian, Inc., Public Relations, E-mail: pr@varianinc.com , Tel. +1 (925) 942-4703

Michael C. Arnold Joins Gardner Denver, Inc. Board of Directors

QUINCY, IL, Jun 03, 2009

Gardner Denver, Inc. (NYSE: GDI) announced today that its Board of Directors appointed Mr. Michael C. Arnold to serve as an independent director of the Company until the 2012 annual meeting of its stockholders and until his successor is duly appointed and qualified. Mr. Arnold will serve on the Board's Management Development and Compensation Committee. The addition of Mr. Arnold expands the Company's Board to nine members.

Mr. Arnold is the Executive Vice President and President of the Bearings and Power Transmission Group at The Timken Company, a publicly held manufacturer of innovative friction management and power transmission products and services. Mr. Arnold joined Timken in 1979 and has held a series of senior management positions, including President of Timken's former Industrial Group, a position he held from 1999 to 2007 when he was promoted to his current position. Mr. Arnold earned a B.S. degree in mechanical engineering and a Master's degree in sales and marketing, both from The University of Akron. He also completed the Advanced Management Program at Harvard University.

Gardner Denver, Inc., with 2008 revenues of approximately $2.0 billion, is a leading worldwide manufacturer of reciprocating, rotary and vane compressors, liquid ring pumps and blowers for various industrial and transportation applications, pumps used in the petroleum and industrial market segments, and other fluid transfer equipment serving chemical, petroleum, and food industries. Gardner Denver's news releases are available by visiting the Investor Relations page on the Company's website.

Contact:

Helen W. Cornell, Executive Vice President, Finance and CFO, Tel. +1 (217) 228-8209

www.GardnerDenver.com

Introducing the NASH Vectra SX Series of Liquid Ring Vacuum Pumps & Compressors

Trumbull, CT, May 11, 2009

Gardner Denver Nash is pleased to introduce its newest line of industrial liquid ring pumps and compressors: the NASH Vectra SX series. Designed from the ground up to meet the widespread needs of the process industry, the Vectra SX adds five models to Nash's Vectra series in the 1 ½ to 10 HP range, providing the right solution for small capacity vacuum pump requirements. Designed to use less energy and consume less operating liquid than competitive models, it is possible to save the user as much as 40% on power consumption and 50% on water usage.

The NASH Vectra SX series features reliable long life, high efficiency, and the flexibility to tailor the pump to your specific needs:

- Reliability - In order to keep your facility running, the Vectra SX has been designed with optimized internal passages and low operating speeds that will ensure a long reliable operating life.

- Energy and Operating Liquid Savings - In order to lower product life cycle costs, and to provide a more environmentally friendly solution, the Vectra SX has been designed to use less energy and consume less operating liquid than competitive models. With the potential energy and water savings it is possible for the Vectra SX pump to pay for itself in less than a year.

- Flexibility - Three variations of the pump have been developed to provide the optimum solution to different process needs.

o A high vacuum version that provides efficient performance to 1" HgA

o A "water handling" version designed for large amounts of process water or carryover (up to 10 times the normal amount)

o A compressor version designed for a wider pressure range

o Two drive arrangements: Monoblock and Pedestal

- Materials of Construction Availability

o Cast iron with a precision cast 316 stainless steel impeller and a corrosion resistant pump body

o All 316 precision cast stainless steel

Reliability, efficiency and flexibility, coupled with the comprehensive Gardner Denver Nash expertise, service and technical support, provide you with unmatched value in liquid ring pumps.

About the company:

Nash is a division of Gardner Denver, Inc. For more than 100 years, Nash has engineered and produced liquid ring vacuum pumps and compressors and Engineered-to-Order systems. Nash products have operated dependably for decades in a wide variety of applications. In addition, Nash professional service is available to keep your pumps and systems running efficiently.

Contact:

Amy Harold, Marketing - www.GDnash.com

E-mail: nash@gardnerdenver.com, Tel. 1-800-553-NASH

Gardner Denver, Inc. announces manufacturing consolidation project

QUINCY, IL (April 13, 2009)

Gardner Denver, Inc. (NYSE: GDI) announced the consolidation of the North American manufacturing operations of its compressor and vacuum pumps used in OEM applications into its Monroe, Louisiana facility. Production from the Company’s Sheboygan, Wisconsin operations will be transferred to Louisiana over the next twelve months. The project is expected to be completed by March 31, 2010.

Mr. Barry Pennypacker, President and Chief Executive Officer of Gardner Denver, said, “Although a number of factors influenced the decision to consolidate production in Monroe, our primary focus was to ensure the long-term competitiveness of the business by continuing to drive cost and inefficiencies out of the operations, while increasing our flexibility through the implementation of the Gardner Denver Way. Reaching a decision to close the Sheboygan operation was difficult and we deeply regret the impact that this closure will have on our Sheboygan employees and the local community. In the long-term, we believe this consolidation positions us with the best business solution and is in the best interests of Gardner Denver and its shareholders. We appreciate the effort and commitment demonstrated by state and local government agencies, as well as the extensive employee support received in both Wisconsin and Louisiana.

“As part of moving the operations to Monroe, the state of Louisiana, through its Rapid Response Fund Grant, will reimburse Gardner Denver for most of the costs incurred in relocating its equipment and personnel from Sheboygan, provide annual payroll and sales tax rebates through its Quality Jobs Program and facilitate employee recruitment and training through its Louisiana FastStart Program. The City of Monroe will assist in the construction of a new 124,000 square foot manufacturing facility adjoining our existing manufacturing operation.”

The Company currently employs approximately 366 people in Sheboygan, including approximately 280 in manufacturing operations and related support functions, and 76 people in Monroe.

Contact: Helen W. Cornell, Executive Vice President, Finance & CFO, Tel. +1 (217) 228-8209

Pfeiffer Vacuum - Best results in the company’s history. Dividend again raised.

Asslar, Germany, March 25, 2009.

Pfeiffer Vacuum, one of the leading manufacturers of high-quality vacuum pumps, measurement equipment and complete vacuum systems, announces its full, audited results for the 2008 fiscal year, which surpassed expectations. With a proposed dividend of € 3.35 per share and a dividend yield of 7.1 percent, Pfeiffer Vacuum is the highestdividend issue in the TecDAX.

Sales revenues rose by 3.1 percent in fiscal 2008, from € 192.0 million to € 198.1 million, with customers in the analytical industry accounting for around one quarter of this total. Sales revenues in this market segment were up by 5.4 percent from € 47.9 to € 50.5 million. Manufacturers of analytical equipment in the United States, the United Kingdom, Japan and Germany rely upon the dependability and performance of products from Pfeiffer Vacuum.

It was also possible to increase sales in the heterogeneous Industrial Applications market segment, by 4.1 percent from € 44.7 to € 46.5 million. Large pumping stations for steel degassing are an important element in the production of high-quality stainless steep products that are free of air inclusions. During the year under review, pumping stations and leak detection systems were also supplied for solar thermal systems in Spain and New Mexico (U.S.A.). Moreover, pumps for electron beam welding systems that are used in joining modern materials and for metallurgical furnaces also contributed to this sales growth.

In the Coating market segment, sales revenues advanced sharply by 15.4 percent, from € 39.3 to € 45.4 million, fuelled especially by growth in the solar industry. In addition to completing the first major contract for systems used in the fabrication of thin layer solar cells and commencement of work on the follow-on order for Q-Cells subsidiary Solibro, numerous orders for pumps and measurement equipment were also delivered to prominent manufacturers of photovoltaic systems. The solar sector continues to be the largest sales driver in the market segment of Coating. In fiscal 2008, this segment accounted for around 12.5 percent... more

more facts and figures: download

Pfeiffer Vacuum Technology AG - www.pfeiffer-vacuum.com

Gudrun Geissler, Investor Relations, email: Gudrun.Geissler@pfeiffer-vacuum.de, Tel. +49 (0) 6441 802-314, Fax +49 (0) 6441 802-365

Oerlikon Leybold Vacuum introduces compact vacuum pump for analytical applications

Cologne, Germany - March 17, 2009

Oerlikon Leybold Vacuum, a leading supplier of advanced vacuum systems for use in manufacturing and analytical processes, presents the SOGEVAC SV16 BI, a new single-stage oil-sealed rotary vacuum pump designed for demanding analytical applications that require low-noise operation and compact design. The pump, which is an ideal match for mass spectrometry equipment, is being exhibited at the Pittcon 2009 Conference & Expo, Booth 4265.

Drawing on Oerlikon Leybold Vacuum's extensive engineering and applications experience, and incorporating many large and small design innovations, the SOGEVAC SV16 BI offers equivalent performance in mass spectrometry applications, comparable to two-stage pumps, but with a smaller footprint and at lower cost. At the same time, it offers quieter operation and better performance than most single-stage pumps.

The new pump can be easily integrated into a wide range of analytical instruments. External exhaust filtration and oil return is not needed, due to the SOGEVAC SV16 BI's internal exhaust filter and oil recovery system. In addition, it can operate at all pressures continuously without any add-on accessories.

Features of the new SOGEVAC SV16 BI include:

- 20.5 CFM operation at 60 Hz, at up to 3.8 x 10-2 Torr ultimate pressure

- Excellent compatibility as a fore-vacuum pump in conjunction with modern wide-range turbomolecular pumps

- Over-pressure relief valve integrated into the internal exhaust filter, with quick access for filter replacement and oil recovery cleanout

- Excellent oil-gas pre-separation

Coming soon: Operation with mineral, PFPE or synthetic oil allowing up to one-year oil lifetime

"Our product development teams work closely with our technically trained sales personnel, applications engineers, service teams and manufacturing experts. As a result, our new product designs incorporate extensive knowledge of real-world application needs and customer preferences, as well as our 158 years of experience producing vacuum pumps for some of the world's most demanding installations," noted Marcus Sander, CMO of Oerlikon Leybold Vacuum. "The SOGEVAC SV16 BI offers analytical instrument developers an excellent new vacuum system option that can help their equipment perform better and require less end-user maintenance."

The SOGEVAC SV16 BI is available immediately through Oerlikon Leybold Vacuum's global sales network.

Oerlikon Leybold Vacuum GmbH - Bonner Str. 498, 50968 Cologne, Germany

Christina Steigler, Marketing & Communications, Tel. +49 221 347 1261, Fax +49 221 347 1083

Only the Manufacturer's vacuum pump service can guarantee expert maintenance and repairs

Nuremberg (Germany), Mar. 12, 2009

No two service contracts are the same and a low quotation for the repair of a pump should not be the only decisive argument for placing an order. Again and again, the operators of pumps and systems find this a somewhat painful experience. A case in point can be seen in the repair of two liquid ring vacuum pumps in a paper mill.

Liquid ring vacuum pumps used in a paper mill have given reliable service for many years. As a result of the stresses imposed by the production process over the years, the pumps eventually suffered wear and material attrition. The operator therefore decided to take them out of service so that they could be repaired. For cost reasons, however, this work would not be carried out by the manufacturer, Gardner Denver Nash, but by a local service workshop.

Upon the completion of the repairs, however, both machines showed extremely poor performance. After a number of futile attempts to improve their performance, the machines were again taken out of service and this time sent to the Nash Service Center, where they were tested on a test stand. Here, the first diagnosis was reinforced when both machines performed poorly during their test runs. As part of the troubleshooting process, both pumps were next disassembled, revealing the full extent of the problem, namely inexpert repair work using replacement parts which were unsuitable and lacked dimensional accuracy. After they had been expertly repaired in the Nash Service Center, both pumps were returned to service where they performed reliably and in accordance with their normal performance parameters. For the operator of the paper mill, however, the decision to base the repair work on costs alone had a boomerang effect. Higher repair costs were associated with longer stoppage times, while the recovery of payments for the work from the local service workshop entailed further administrative expense.

Liquid ring vacuum pumps are tough machines, based on decades of know-how and experience of the manufacturer. Gardner Denver Nash (a result of the merger of Nash Engineering with Siemens/elmo) has been making liquid ring vacuum pumps and compressors for more than hundred years. The experience acquired over such an extensive period is invaluable, not only in the development of new machines but also, and quite particularly, in the maintenance and repair of pumps. The manufacturer's unique know-how in terms of functions, dimensions and materials provides the basis for professional services, available worldwide, which in turn supports customers in keeping their vacuum pumps and compressors operating throughout decades of service.

About the Company:

Gardner Denver Nash is the Nash Division of Gardner Denver, Inc. Originating from nash_elmo Industries, the company is the world's leading manufacturer of liquid ring vacuum pumps, compressors and engineered systems. For more than 100 years, Gardner Denver Nash has engineered and produced liquid ring pumps and vacuum and compressor systems for the most demanding applications in a variety of fields and industries.

download: Manufacturer's vacuum pump service (pdf-Version)

Nash - Zweigniederlassung der Gardner Denver Deutschland GmbH - www.GDnash.com

Wolfgang Kraft, Marketing, wolfgang.kraft@gardnerdenver.com, Tel. +49 (0)911 1454-7771, Fax +49 (0)911 1454-7777

Turbopumpe HiPace™ Plus - Ideal für Anwendungen in der Analytik!

Asslar, 11. März 2009

Very low vibration spectrum

In addition to the current new product line of HiPace 10-700 l/s turbopumps, Pfeiffer Vacuum has brought to market new compact yet powerful turbopumps under the name, HiPace 300 Plus. This pace-setter is available with pumping speed up to 260 liters per second. The pump is characterized by its reduced and improved vibration spectrum which makes it ideal for analytical applications such as electron microscopy and high-end mass spectrometry. Furthermore, the pump offers high cost-effectiveness due to extended service intervals. The improved rotor design gives both, high pumping speeds and high gas throughputs, coupled with very good compression for light gases.

New drive electronics with reduced run-up time

The integrated HiPace drive electronics reduce the need for cumbersome and costly cabling. The use of innovative materials has doubled the service life of the drives. And run-up time has also been reduced, so that the instrument is faster available. Remote and sensor functionalities allow analysis of pump data, such as temperatures. The functional aluminum housings make these pumps extremely light in weight. A sealing gas connection safeguards the bearings against particulate matter or oxidizing gases. This translates high reliability in both light duty and harsh duty applications. And their quiet operation and improved gas loads are setting new standards.

Pfeiffer Vacuum GmbH - www.pfeiffer-vacuum.com

Sabine Trylat, Public Relations, email: Sabine.Trylat@pfeiffer-vacuum.de, Tel. +49 (0) 6441 802-169, Fax +49 (0) 6441 802-883

Erich Mohrdieck and Roger McMahon Co-Presidents of SIHI

March 9, 2009

With immediate effect Christoph v. Grolman, Co-CEO of TBG Holdings NV (TBG) and Chairman of SIHI Group BV Supervisory Board (SIHI), is pleased to announce the promotion of Erich Mohrdieck and Roger McMahon to Co-Presidents of SIHI following the resignation of Jürgen Arnold.

Jürgen Arnold, after more than 5 years with the Group, has decided to pursue an alternative opportunity for the next step in his career. TBG recognise and value highly the strong contribution that Jürgen has made to the business during his period of management when SIHI has developed significantly.

The new senior management appointments are supported by Jürgen and he will work with TBG and SIHI management to affect a smooth handover thereby ensuring minimum disruption to the business.

TBG is proud that, with Erich and Roger, they have two candidates from within the organisation to share the management of SIHI as the business develops further.

Christoph v. Grolman

Co-CEO of TBG Holdings NV (TBG)

www.sterlingsihi.com

Edwards to supply liquid ring pumps for new power station in India

Crawley, UK, Feb. 18, 2009

Leading vacuum technology company Edwards has won a multi-million Euro contract to supply liquid ring vacuum pump systems for three 660MW generating units at the Super Thermal Power Project Stage 1 at Sipat, State of Chattisgarh, India.

The contract has been awarded by OJSC Power Machines of Russia, who are supplying the majority of the equipment for the power station. It will be run by NTPC, India’s largest power generating company.

The SHR series liquid ring pumps have capacities from 500 to 5000 m3h-1 and will be used for air evacuation from the main and drive turbine condensers, ensuring that they remain at the required operating pressure for maximum turbine efficiency. The systems are based upon Edwards’ standard power packages, customised to meet the customer’s specific requirements, and are scheduled to be delivered over the next few months.

The liquid ring pump systems comprise a two-stage vacuum pump with a spheroidal graphite impeller to improve efficiency and extend life. They have a unique ability to handle wet gases without damage to the pump, making them ideal for condenser air extraction, where the incoming non-condensable air load is saturated with steam.

The systems can operate across the complete vacuum range, from atmospheric pressure to 30 mbar, with a relatively constant pumping speed. They are also tolerant of small particles in the gas stream, have a low noise and vibration level and low maintenance requirements.

Edwards’ experience in this field and technical capabilities were instrumental in securing the contract. Edwards products are already installed in other NTPC power stations across India, and the company provides strong technical support in both Russia and India.

“The Edwards pump packages are ideally suited to for this application, and will integrate very effectively with the turbines and condensers we are supplying, helping us to maximise condenser and turbine efficiency,” explains Olga Dranishnikova, head of procurement at Power Machines. “We look forward to working with the Edwards team in Russia and India to deliver this project to NTPC.”

For further information contact:

Edwards vacuum, Manor Royal, Crawley, West Sussex, RH10 9LW, UK

email: info@edwardsvacuum.com, Tel. +44 1293 528844.

Siemens Receives SSAB Contract for Vacuum Tank Degassing Facility

Atlanta, Georgia, USA, Jan 28, 2009

Svenskt Stål AB (SSAB) has awarded Siemens a contract for more than $14 million for a Vacuum Tank Degassing (VTD) facility for its Mobile, Ala. facility. Siemens is scheduled to complete the VTD project in May 2010. This VTD project is part of a major investment program announced by SSAB in August 2008 with the aim to further develop the company’s production base in Sweden and the United States. The investment will result in a major increase of the volume of quenched and tempered steels. The installation of the VTD facility will enable SSAB to provide more value-added products to its customers.